Behind the Scenes: How Rigging Keeps Shipyards and Ports Moving

In the complex ecosystem of shipyards and ports, few things are as critical — yet as invisible — as effective rigging. At Hercules Crane & Lifting Supplies, we believe that robust rigging systems, trained riggers, and quality lifting supplies are the backbone of smooth operations. In this post, we’ll pull back the curtain on how rigging keeps shipyards and ports running, spotlight key Canadian industry insights, and invite you to partner with us for best-in-class solutions.

The Invisible Engine: Rigging’s Role in Ports & Shipyards

Rigging — the gear and expertise needed to move, lift, secure and place heavy loads — is at the heart of port and shipyard operations. Whether it's lifting a section of hull into place at a shipbuilding facility or moving containers at a busy port terminal, rigging systems ensure that the heavy-duty demands are met safely and efficiently.

In a shipyard setting, riggers determine suspension points, select appropriate cables, winches and nets, and coordinate with crane operations to manoeuvre large modules or ship sections. In port operations, rigging supports container cranes, bulk-cargo handling equipment, and the movement of oversized loads.

Without professional rigging, operations would slow, downtime would increase, and safety risks would spike. Proper rigging ensures alignment, balance, and load control — all of which keep shipyards and ports moving.

Canadian Industry Insights: Why Rigging Matters More Than Ever

Growing Marine & Port Activity

Canada’s marine and port industry remains a vital part of the economy — from Atlantic Canada to the Great Lakes and west coast. For example, Ontario Shipyards reports launching full Seaway-max vessels built in Ontario and over 100 dry-docking and refit projects on Canadian Coast Guard vessels. As shipyards undertake build, repair and conversion work, rigging demands increase.

Specialized Skills & Safety Standards

Rigging in shipyards demands specialized skill sets. Riggers must not only handle cables, nets and suspension systems but also understand load behaviour in dynamic marine environments. The need for rigorous safety standards is heightened by maritime regulations, heavy modules, and often constrained spaces.

Equipment & Heavy-Lift Challenges

Modern port and shipyard operations handle massive loads: container cranes, modules, and ship sections. This means that rigging suppliers must provide high-capacity gear and work with engineering teams to ensure safe lifts and movements. As one provider notes: “With 100+ lines … we have a capacity of over 5,000 tons … our equipment and staff have played a major role in building barges and ships across Canada.” Groupe Bellemare

Expanding Shipbuilding and Port Operations

Canada’s shipbuilding and marine repair industries are thriving. From the Great Lakes to the Atlantic Coast, shipyards are busier than ever, driven by government defense contracts, fleet renewal projects, and commercial marine demand.

The Halifax Shipyard, operated by Irving Shipbuilding, is a cornerstone of this activity. As Canada’s largest shipbuilding facility, it’s responsible for constructing the Royal Canadian Navy’s Arctic and Offshore Patrol Ships and other future fleet projects under the National Shipbuilding Strategy. This massive operation relies on precise, reliable rigging systems to handle the immense steel blocks, sections, and components that form each vessel.

At Hercules Crane & Lifting Supplies, we’re proud to play a part in supporting the Halifax Shipyard’s success — providing high-quality rigging gear, lifting hardware, and inspection services that help keep this world-class facility running safely and efficiently.

What Rigging Looks Like in Practice

-

Module installation: In a shipyard, large prefabricated modules are lifted into place. Rigging systems must coordinate with cranes, ensure balance, and align modules precisely.

-

Crane relocation/maintenance: At ports, container or ship-loader cranes must occasionally be repositioned or maintained. Specialized rigging gear and control over huge loads become critical.

-

Bulk cargo handling: In terminals, bulk material or oversized equipment is lifted and moved. Rigging provides anchor points, load containment and safe lifting envelopes.

-

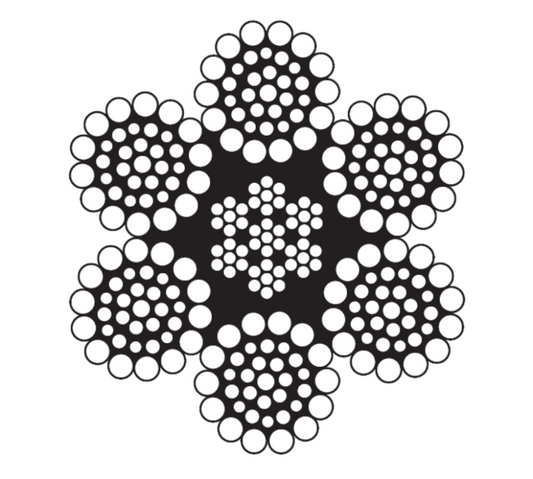

Marine environment demands: Salt air, variable weather conditions, and marine growth all influence rigging gear selection — from wire slings to shackles, to synthetic rope. Routine inspection and replacement are essential.

Why Getting Rigging Right Matters For Your Facility

-

Operational Efficiency – Proper rigging avoids delays. A lift that goes smoothly keeps the schedule intact; a mis-rigged load can halt an entire shift.

-

Safety & Compliance – Poor rigging leads to dangerous incidents. Compliance with Canadian safety standards, proper slings, certified gear — these are non-negotiable.

-

Cost Management – Downtime, equipment damage and re-work all cost money. Investing in right rigging gear and expertise upfront reduces unexpected costs.

-

Reputation & Reliability – Shipyards and ports rely on repeat business. Projects that run smoothly build credibility. Rigging is a behind-the-scenes contributor to that reliability.

How Hercules Crane & Lifting Supplies Supports Shipyards & Ports

At Hercules Crane & Lifting Supplies, we understand that rigging for shipyards and ports isn’t generic. It requires specialized gear, site understanding and rigorous safety practices. We offer:

-

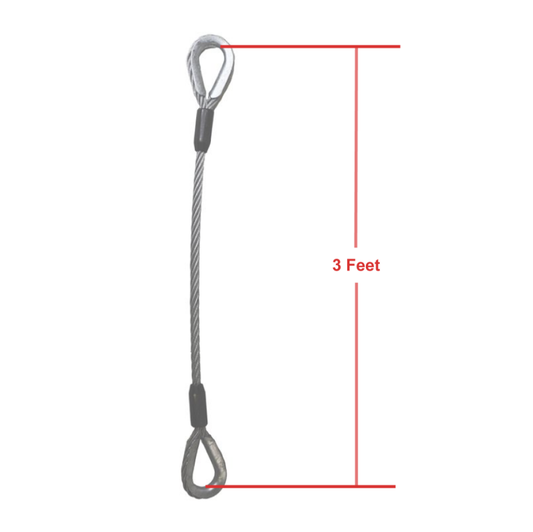

Comprehensive rigging hardware – Wire rope slings, chain slings, synthetic slings, shackles, hooks — all certified and tailored for marine/port environments.

-

Custom assemblies – For complex lifts we design and assemble rigging solutions to your specifications.

-

Inspection & testing services – Rigging gear in marine environments must be inspected more frequently. We provide inspection, testing and certification to keep your gear compliant.

-

On-site consultation – Our team works closely with clients in shipyards and ports to identify rigging challenges, propose solutions and support lifts that rely on precision.

-

Regional expertise – Based in Canada, we understand the particular conditions of Canadian shipyards and ports — including Atlantic Canada’s marine environment, logistics, and safety requirements.

Best Practices for Rigging at Shipyards & Ports

-

Use certified rigging gear: Ensure all slings, shackles, ropes and hardware meet Canadian standards and are inspected regularly.

-

Plan the lift thoroughly: Coordinated lift planning reduces risk — assessing centre of gravity, load path, interference, and site conditions.

-

Consider the marine environment: Salt corrosion, high humidity, tidal movement — rigging gear must withstand these factors and inspections should account for them.

-

Regular inspection & maintenance: Rigging gear must be removed from service at signs of wear, corrosion or deformation.

-

Partner with experienced rigging providers: Working with a specialist who understands shipyards, ports and marine rigging demands ensures smoother operations.

Partner with Hercules Crane & Lifting Supplies

If you’re operating a shipyard, port terminal, marine repair facility or bulk-cargo dock in Canada, you can’t afford to leave rigging to chance. At Hercules Crane & Lifting Supplies, we are ready to be your dedicated partner in rigging solutions — from supply, custom assemblies, inspection and consultation. Let us help you keep your operations moving — safely, efficiently and reliably.

Contact us today to discuss your rigging needs: call 1 (877) 461-4876 or visit Hercules Crane & Lifting Supplies When it comes to rigging in shipyards and ports, choose the partner that understands the demands of the marine environment, the Canadian industry and the importance of getting it right every time.