Understanding Center of Gravity in Lifting Operations

When it comes to lifting operations, understanding the center of gravity (CG) is one of the most crucial elements in maintaining load stability and safety. Whether you’re using a crane, hoist, or rigging assembly, misjudging a load’s center of gravity can lead to dangerous swings, tip-overs, or dropped loads.

In this guide, we’ll break down what the center of gravity is, why it matters, how to find it, and how Hercules Crane & Lifting Supplies helps ensure every lift is balanced, controlled, and safe.

What Is the Center of Gravity?

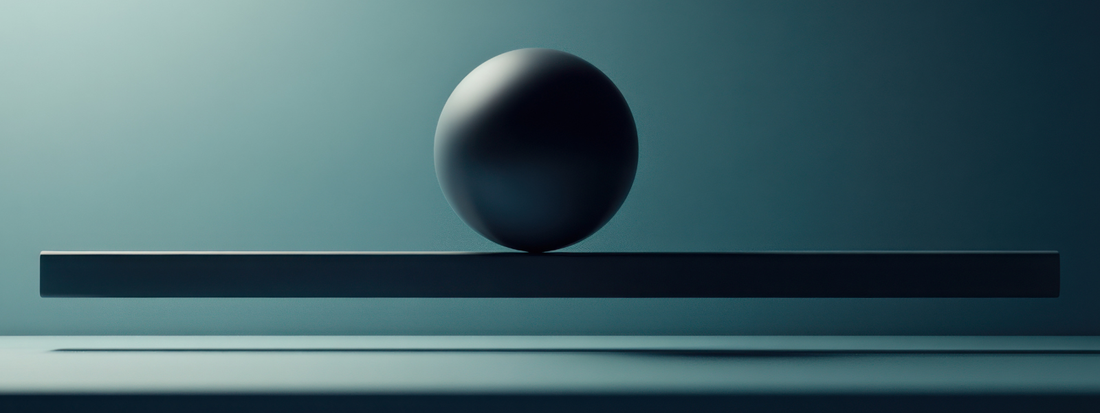

The center of gravity is the point in an object where its total weight is considered to act. If you were to suspend an object perfectly from its center of gravity, it would remain level and balanced.

Every object—whether a simple I-beam or a complex, uneven load—has a center of gravity. Its location depends on the shape, density, and distribution of weight.

For example:

-

A uniform steel block has its CG at its geometric center.

-

A loaded pallet may have its CG shifted toward the heavier side.

-

A machine or vehicle with components on one end may have an offset CG that’s not visually centered.

Understanding where that point lies is key to ensuring the load remains stable during lifting and movement.

Why Center of Gravity Matters in Lifting Operations

When a load is lifted, gravity acts vertically downward through the CG, while the lifting force acts upward through the hook or sling assembly.

For a lift to be stable, these two forces must align.

If they don’t, the load will:

-

Tilt or rotate as it leaves the ground

-

Put unequal stress on slings and lifting points

-

Potentially tip over, slip, or fall

A misaligned center of gravity doesn’t just cause load damage—it poses a serious risk to workers, rigging gear, and nearby structures.

Key Risks of an Improper CG:

-

Uncontrolled load movement: The load may rotate unexpectedly once airborne.

-

Overloaded rigging components: One sling may take on more force than rated, causing failure.

-

Crane instability: A shifting load can create side-loading forces on the crane boom.

-

Dropped loads: In severe cases, the entire lift can fail, leading to catastrophic accidents.

How to Find the Center of Gravity

Determining a load’s CG can range from straightforward to complex, depending on the load’s shape and weight distribution. Here are the most common methods used in lifting operations:

1. Visual Estimation

For simple, symmetrical objects like beams, pipes, or plates, the CG is typically at the geometric center. Marking that midpoint helps ensure rigging is attached evenly on both sides.

2. Weight Distribution Analysis

When lifting irregular or uneven loads, such as machinery, vehicles, or fabricated structures, riggers must assess how the weight is distributed.

This often involves:

-

Reviewing blueprints or drawings

-

Checking manufacturer documentation

-

Calculating component weights to determine the expected balance point

3. Trial Lifts

If the exact CG is uncertain, riggers perform a test lift:

-

The load is slowly lifted a few inches off the ground.

-

The rigging team observes any tilt or imbalance.

-

Adjustments are made by repositioning lifting points until the load hangs level.

This method is often used for custom or one-off lifts.

4. Using Lifting Beams or Spreaders

When the CG is offset, lifting beams or spreader bars help distribute lifting forces evenly and control load orientation. These devices allow riggers to adjust sling lengths or attachment points to match the actual CG location.

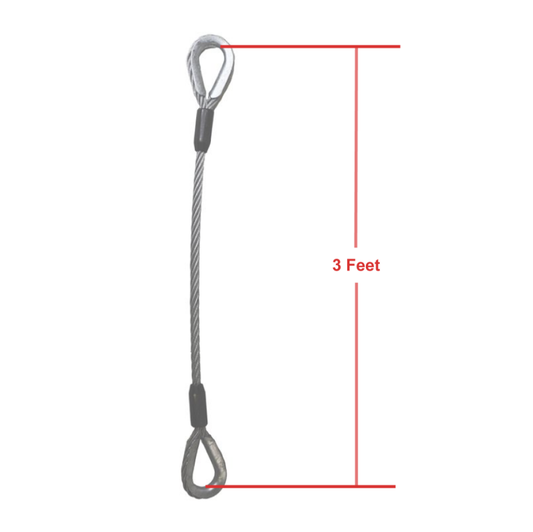

How Center of Gravity Affects Rigging Setup

Understanding the CG directly influences how you plan your rigging configuration. The goal is always to align the hook (or crane line) vertically above the center of gravity.

A few critical setup principles:

-

Symmetrical loads: Use equal-length slings attached at equal distances from the CG.

-

Asymmetrical loads: Adjust sling lengths or pick points so that the load remains level.

-

Low CG loads: More stable and less prone to tipping.

-

High CG loads: Require careful handling—these are more likely to roll or tilt during lifting or movement.

Example:

If a generator has heavier internal components on one side, the CG will be closer to that side. By shortening one sling or adjusting the lifting beam, the rigger ensures the hook remains directly over the CG, keeping the generator balanced through the lift.

Practical Tips for Maintaining Load Stability

-

Plan every lift in advance

Identify load weight, dimensions, and potential CG offset before choosing rigging gear. -

Mark the center of gravity

Clearly label the CG point on the load whenever possible. This improves coordination between riggers, crane operators, and signalers. -

Use certified lifting points and hardware

Ensure all hooks, shackles, eye bolts, and slings are rated and inspected according to Canadian OHS and CSA standards. -

Never guess

When uncertain, perform a test lift or consult a qualified rigging engineer or technician. -

Maintain communication

Crane operators and riggers should have clear hand signals or radio contact to adjust quickly if the load shifts.

The Role of Training and Expertise

Proper understanding of center of gravity isn’t just theoretical—it’s a learned skill built through training, certification, and experience.

Professional riggers and crane operators undergo specialized courses in:

-

Load calculations

-

Sling angle effects

-

Rigging hardware selection

-

Safe lifting practices

At Hercules Crane & Lifting Supplies, our experts not only supply certified rigging hardware but also provide on-site inspections, load testing, and training to help companies meet CSA and OHS compliance standards.

How Hercules Crane & Lifting Supplies Can Help

Balancing a lift safely takes more than the right equipment—it takes the right knowledge. Hercules offers:

-

Custom rigging assemblies designed for your specific lifting needs

-

Pull and break testing services to verify gear performance

-

Inspection and certification programs for all lifting hardware

-

Expert guidance from certified technicians who understand how CG affects every aspect of your operation

Whether you’re planning a lift in construction, manufacturing, or marine environments, our team ensures every load is safe, balanced, and compliant.

Final Thoughts

The center of gravity may be invisible, but its impact is felt in every safe and successful lift. Understanding where your load’s CG lies—and aligning your lifting plan accordingly—can be the difference between efficiency and accident.

By combining rigging expertise, proper planning, and certified Hercules equipment, you can keep your lifting operations steady, predictable, and secure.